You probably all know the traditional Forstner bit. In 1874 it was invented by the American Benjamin Forstner, who was born in Beaver County, Pennsylvania. B. Forstner was a gunsmith,

inventor and dealer of textile goods. At that time it was customary, that drill bits for wood were produced with a centre point, working like a wood screw. Once located and turned,

the bit pulled itself more or less without any effort into the wood. Perfect for through boring. But what to do, if you wanted to drill e.g. a stud hole, like for a weapon?

For this B. Forstner invented a bit with centre point,

inventor and dealer of textile goods. At that time it was customary, that drill bits for wood were produced with a centre point, working like a wood screw. Once located and turned,

the bit pulled itself more or less without any effort into the wood. Perfect for through boring. But what to do, if you wanted to drill e.g. a stud hole, like for a weapon?

For this B. Forstner invented a bit with centre point,

which was not pulling itself into the material. Beside two main cutting edges these bits were fitted with two closed circumferential cutting edges.

which was not pulling itself into the material. Beside two main cutting edges these bits were fitted with two closed circumferential cutting edges.

Nowadays the power drills and cordless drills are working with a substantial higher speed than in Benjamin Forstner’s day.

Traditional Forstner bits – especially the super cheap ones,

which often travelled from so far – often reach or exceed their limits at modern speeds. The results are blazing hot Forstner bits, which start to smoke during application.

Once such a Forstner bit has reached such a temperature, its material structure changes. You will notice that even if you have regrinded this tool, the pleasure will not last long.

Traditional Forstner bits – especially the super cheap ones,

which often travelled from so far – often reach or exceed their limits at modern speeds. The results are blazing hot Forstner bits, which start to smoke during application.

Once such a Forstner bit has reached such a temperature, its material structure changes. You will notice that even if you have regrinded this tool, the pleasure will not last long.

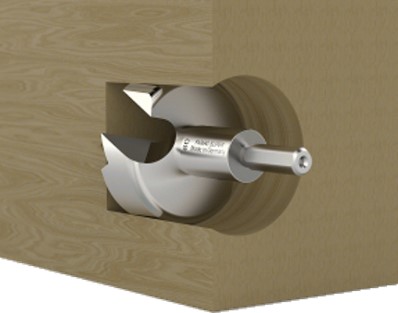

The FAMAG Forstner bit is made of alloyed tool steel. It is fitted with a centre point with an especially clever geometry.

This centre point has a cutting character and reduces – especially when you are boring larger diameters – the feed force considerably. Two main cutting edges are doing the cutting of the wood.

Before the main cutting edges can start their work, the so called taper taps have to do the first cuts into the wood. The result is a proper surface of the hole frame without any tears or fringes.

This centre point has a cutting character and reduces – especially when you are boring larger diameters – the feed force considerably. Two main cutting edges are doing the cutting of the wood.

Before the main cutting edges can start their work, the so called taper taps have to do the first cuts into the wood. The result is a proper surface of the hole frame without any tears or fringes.

The traditional Forstner bit has a closed circumferential cutting edge.

During pre-cutting this causes higher temperatures and friction because this cutting edge is in contact with the surface of the material over the entire length. This is different with the FAMAG Forstner bit!

The traditional Forstner bit has a closed circumferential cutting edge.

During pre-cutting this causes higher temperatures and friction because this cutting edge is in contact with the surface of the material over the entire length. This is different with the FAMAG Forstner bit!

In our modern production, we reset the largest part of the circumferential cutting edge by a few tenths of a millimetre and leave only a very small front part in contact with the material surface. The result is a really cool head!

The FAMAG Forstner bits with a diameter from 6,35 up to 20 mm have a cylindrical shank with Ø 8 mm. All larger diameters are fitted with a shank of Ø 10 mm. We produce the Forstner bit from diameter 6,35 up to diameter 57,15 in metric sizes, but also in “imperial” sizes with an overall length of 90 mm. We have 38 individual sizes and different sets available in our product range.

Forstner bits are constructed for the use in soft wood. Of course they also work very reliably in glulam (glued laminated timber). Due to their two long peripheral cutting edges they have particularly good guiding properties and are therefore perfectly suitable for freehand use. For the processing of hard wood they are not so well suited. Here we recommend the tools of the Bormax family.

More than 10 years ago there was a big comparison test of all well-known Forstner bits of “Fine Woodworking”. This test measured which bits produced the most accurate holes, which bits ejected the chips best and which temperature the chips and the Forstner bits showed after a certain number of holes. The FAMAG Forstner bit was in first place with the rating “best overall”! We were very happy about that and also the fact that products of our competitors had partially toothed circumferential cutting edges but nevertheless were on rear places. Made in Germany is just a guarantee for the finest quality. Like 150 years ago it is still produced in Remscheid. This makes the Forstner bit a real “Made in Germany” tool. Due to its unique selling points it belongs for us to the DELTA-F family of FAMAG.

- perfect guiding properties in freehand application in soft wood by two circumferential cutting edges

- very low heat generation due to circumferential cutting edges with a very special FAMAG geometry

- ideal chip removal from the Forstner bit through round chip channels

Overview of the most important details:

| Product line | 1630 |

|---|---|

| OØ | 6,35 – 57,15 mm |

| SØ | 8 mm resp. 10 mm |

| Overall Length | 90 mm |

| Effective Length | 57 mm |

| Material | Alloyed Tool Steel |

| Speed Ø 35 mm | 1.000 rpm |

| Packaging | Rose-Tube |

| PU | 1 |

(to the Product)

The set of 5pcs including Ø 15/20/25/30/35 mm certainly is the bestseller. But also the set of 8pcs (Ø 15/20/25/30/35/40/45/50 mm) is very popular. In total we have 4 sets with metric sizes and 2 sets with INCH sizes in our product range.

(to the Product)

If you want to drill particularly deep holes with the Forstner bit, we can offer extensions with total lengths of each 80/125/250 and 400 mm. These extensions can be used in any order combination. The Forstner bit can be extended by several extensions of the product line 1639.

(to the Product)

If you want to produce a stud hole with a defined depth, the depth stop of the product line 1621 can be a perfect supplement. You insert the Forstner bit into the guide bushing of the depth stop, adjust the drill depth and fix the tool with help of the attached allen key.

(to the Product)

The Forstner bit is the right tool for you, in case you drill in soft wood only. If you also drill in hard wood, MDF or laminated boards, we recommend the tools of the Bormax family.

(to the Product)

We generally recommend TCT tools (carbide tipped) for drilling in coated chipboards and other hard surfaces. But here, too, we can offer something with which you can even drill freehand - ask for Bormax³ TCT!

(to the Product)