You do all know the traditional Forstner bit. In 1874 it was invented by the American Benjamin Forstner, who was born in Beaver County, Pennsylvania. B. Forstner was a gunsmith, inventor and dealer of textile goods. At that time it was customary, that drills for wood were produced with a centre point, working like a wood screw.

Once located and turned, the drill bit pulled itself more or less without any effort into the wood.

Perfect for through boring. But what to do, if you wanted to drill e.g. a stud hole, like for a weapon? For this B. Forstner invented a drill bit with centre point, which was not pulling itself into the material. Beside two main cutting edges these drill bits were fitted with two closed circumferential cutting edges.

Nowadays the power drills and cordless drills are working with a substantial higher speed than in Benjamin Forstner’s day. The professional user is treating surfaces, which are much harder than in that time. Traditional Forstner bits are overstressed and the results are very often blazing

hot Forstner bits, which start to smoke during application. Completely different with the Bormax! The Bormax belongs to the group of cylinder head drill bits. In fact it is a further development of the Forstner bit, but its name stands for a tool with special unique selling points already for years now.

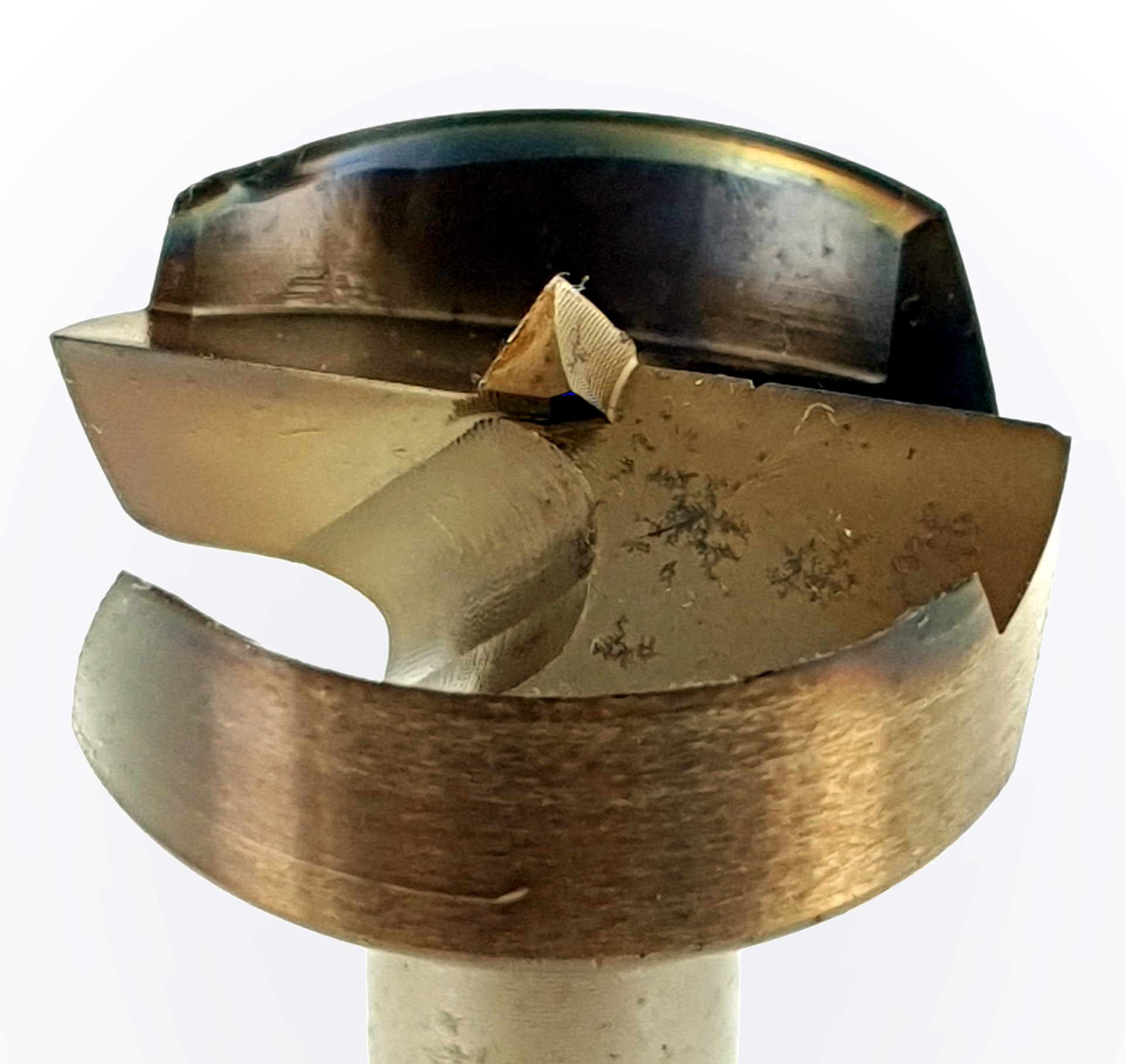

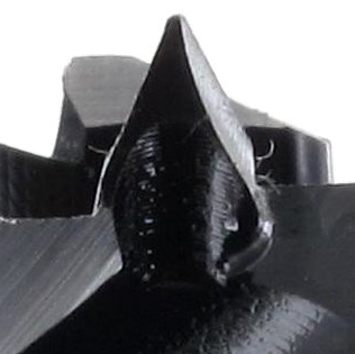

The Bormax® WS is made of alloyed tool steel. It is fitted with a centre point with a

unique clever geometry. This centre point has a cutting character and reduces – especially when you are boring larger diameters – the feed force considerably. Two in reverse order staggered,

grooved main cutting edges are doing the cutting of the wood. So you have an ideal spreading of the cutting forces.

unique clever geometry. This centre point has a cutting character and reduces – especially when you are boring larger diameters – the feed force considerably. Two in reverse order staggered,

grooved main cutting edges are doing the cutting of the wood. So you have an ideal spreading of the cutting forces.

Bevor the main cutting edges can start their work,

the so called taper taps have to do the first cuts into the wood. The result is a proper surface of the hole frame

Bevor the main cutting edges can start their work,

the so called taper taps have to do the first cuts into the wood. The result is a proper surface of the hole frame

without any tearings. The traditional Forstner bit has a closed circumferencial cutting edge. This causes higher temperatures and friction. In order to avoid this completely, the Bormax has new circumferential cutters with grooves.

These are working like many small taper taps. The head of the Bormax® is fitted with fins, which have the effect of cooling fins. The result is a maximal reduce of the heat development.

without any tearings. The traditional Forstner bit has a closed circumferencial cutting edge. This causes higher temperatures and friction. In order to avoid this completely, the Bormax has new circumferential cutters with grooves.

These are working like many small taper taps. The head of the Bormax® is fitted with fins, which have the effect of cooling fins. The result is a maximal reduce of the heat development.

Before the shank of the tool was cylindrical, now it is manufactured hexagonal. This avoids that the drill bit turns in the drill chuck. It has proved particularly successful with the larger diameters.

The Bormax® WS is available in metrical sizes of Ø 8mm – 60 mm and up to a total length of 90 mm also in “imperial” sizes. 43 individual sizes and different sets are available as well.

The Bormax® WS is a universal drill bit for many different kinds of wood. You can drill without effort

in all common soft woods. When working on European hard wood he really shows his teeth.

In the first cut his many taper taps perfectly cut the long wood fibres and you to get an especially proper frame of the hole. More or less without effort the two main cutting edges cut the solid wood.

The chip breaking grooves on the main cutters make the chips small and lead to a perfect removal. This tricky geometry makes a clear less feed force necessary in comparison to traditional tools.

in all common soft woods. When working on European hard wood he really shows his teeth.

In the first cut his many taper taps perfectly cut the long wood fibres and you to get an especially proper frame of the hole. More or less without effort the two main cutting edges cut the solid wood.

The chip breaking grooves on the main cutters make the chips small and lead to a perfect removal. This tricky geometry makes a clear less feed force necessary in comparison to traditional tools.

Even in hard wood the Bormax keeps cool. You will not experience a „smoking“ or „burning“ at Bormax. Not even when working with MDF material or uncoated chipboard.

Same for many plastic materials as e.g. polypropylene, polyethylene, PVC and others. You can use the Bormax freehand with a cordless drill as well as stationary.

Even larger dimensions of more than 50 mm can be produced freehand with a strong cordless drill. All Bormax drill bits are fitted with a hexagonal shank and therefore do not turn in the drill chuck.

Even in hard wood the Bormax keeps cool. You will not experience a „smoking“ or „burning“ at Bormax. Not even when working with MDF material or uncoated chipboard.

Same for many plastic materials as e.g. polypropylene, polyethylene, PVC and others. You can use the Bormax freehand with a cordless drill as well as stationary.

Even larger dimensions of more than 50 mm can be produced freehand with a strong cordless drill. All Bormax drill bits are fitted with a hexagonal shank and therefore do not turn in the drill chuck.

The Bormax® is the only Forstner drill bit with brad point with cutting geometry, with toothed main cutting edges and a circumference cutter with grooves. This geometry is patent-protected. It is manufactured in Remscheid and therefore a “Made in Germany“- tool. Due to these unique selling points it belongs to the DELTA-F family of FAMAG.

- considerably reduced feed force by the perfectly designed centre point and the toothed circumferential cutting edge

- nearly no heat generation thanks to the ingenious geometry of the interrupted circumferential cutting edge with cooling effect

- very good chip removal by the chip breakers on the main cutting edges

- due to its geometry it also drills perfectly in European hard wood

- the hexagonal shank avoids turning in the drill chuck

- still has the unique Bormax® geometry after regrinding

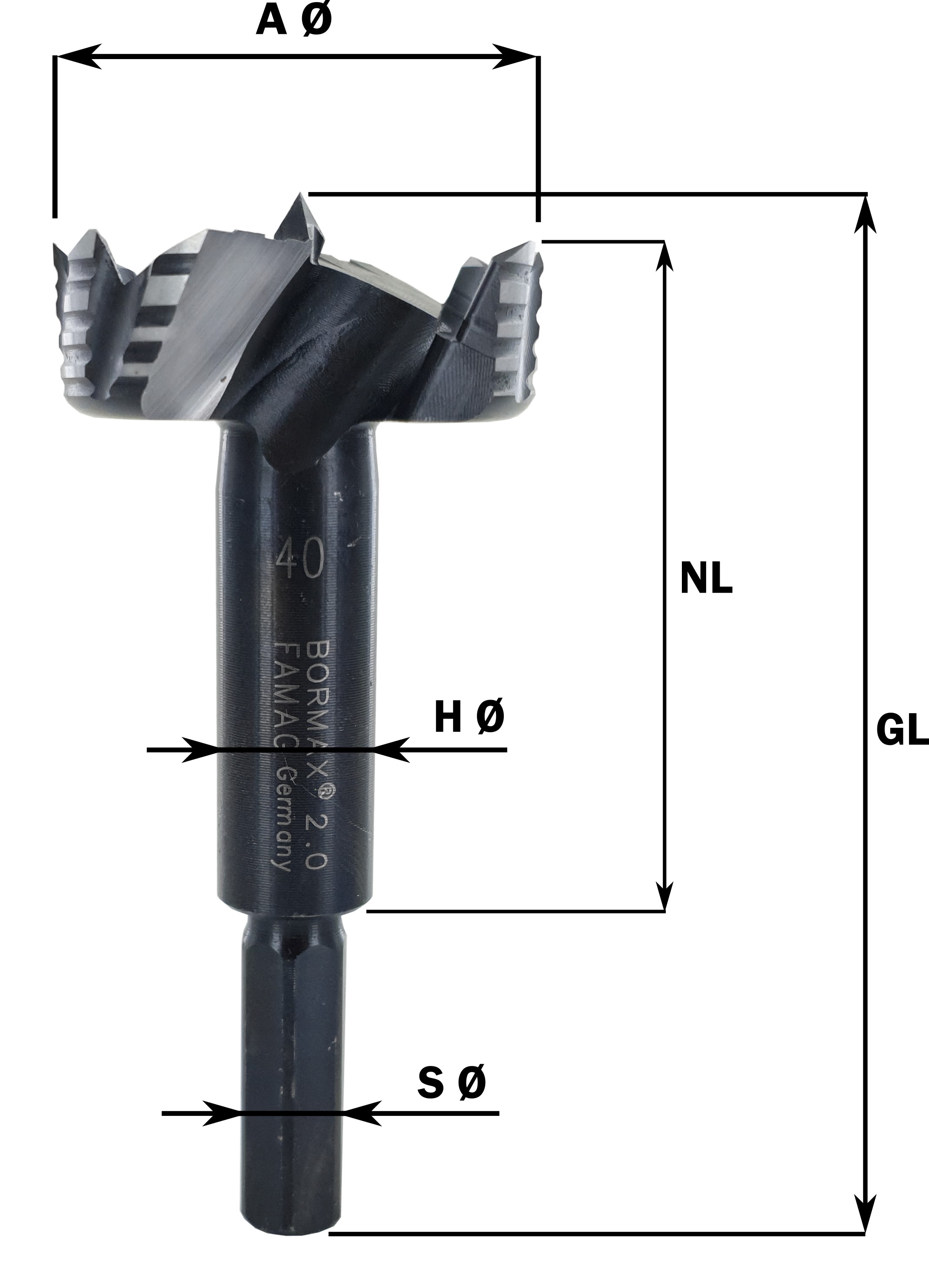

Overview of the most important details:

| Product line | 1622 |

|---|---|

| OØ | 8 - 60 mm |

| HØ | 6,5 - 20 mm |

| SØ | 8 - 13 mm |

| Overall Length | 90 mm |

| Effective Length | 57 mm |

| Material | Alloyed Tool Steel |

| Speed Ø 30 mm | 1.750 rpm |

| Packaging | Blister pack |

| PU | 1 |

(zum Produkt)

Certainly the bestseller is the 5pcs set consisting of Ø 15/20/25/30/35 mm. But also the 8pcs set (Ø 15/20/25/30/35/40/45/50 mm) is very popular. There are 6 sets in metrical dimensions available and 3 sets in INCH dimensions.

(zum Produkt)

If you want to drill special deep holes with the Bormax, we can offer extensions with total lengths of each 80/125/250 and 400 mm. These extensions can be used in any order combination. The Bormax can be extended by several extensions of the product line 1639.

(zum Produkt)

If you want to produce a stud hole with a defined depth, the depth stop of the product line 1621 can be a perfect supplement. You insert the Bormax into the guide bushing, adjust the drill depth and fix the tool with help of the included allen key.

(zum Produkt)

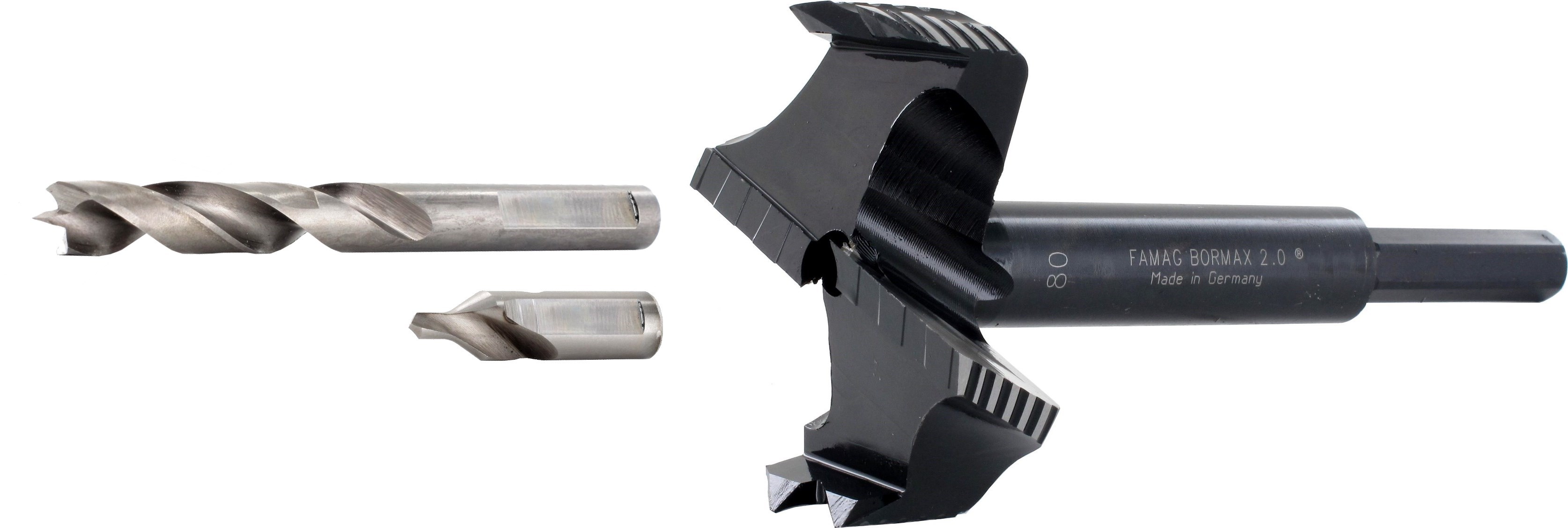

Bormax prima long

The largest diameter we manufacture of Bormax product line 1622 is 60 mm. For drilling still larger diameters, we recommend the product line 1614, Bormax prima long,

with exchangeable pre-drill respectively guiding pin. We produce these tools up to a diameter of 120 mm.

(zum Produkt)

Bormax prima

If you like the idea of an exchangeable pre-drill, you should take a closer look at the Bormax prima, our product line 1624. Here you can replace the centre point with a separate pre-drill.

With this combination, you are able to produce freehand diagonal drillings in almost all wooden materials.

(to the Product)