You do all know the traditional Forstner drill bit. In 1874 it was invented by the American Benjamin Forstner, who was born in Beaver County, Pennsylvania. B. Forstner was a gunsmith,

inventor and dealer of textile goods. These Forstner drills had two taper taps, two main cutting edges and one fixed centre point, which could not be changed or replaced.

inventor and dealer of textile goods. These Forstner drills had two taper taps, two main cutting edges and one fixed centre point, which could not be changed or replaced.

Later drilling applications occurred, in which an existing hole should be drilled at a defined depth. In metal processing this was called “to sink“.

It was very obvious to use for this application in woodworking a cylinder head boring bit or a Forstner drill bit. However, it quickly became clear that this was not at all working well.

The reason for this is that the centre point cannot be held in a hole. Another solution had to be found.

In a first step a smart head changed the fixed centre point to a fixed guiding pin with the same dimension of the drilled hole. Now an impeccable lead was achieved and it could be sunk perfectly.

The disadvantage was, that this tool could only be used for a pre-drilled diameter. As the pre-drilled diameters varied, this solution was not perfect.

The reason for this is that the centre point cannot be held in a hole. Another solution had to be found.

In a first step a smart head changed the fixed centre point to a fixed guiding pin with the same dimension of the drilled hole. Now an impeccable lead was achieved and it could be sunk perfectly.

The disadvantage was, that this tool could only be used for a pre-drilled diameter. As the pre-drilled diameters varied, this solution was not perfect.

In a second step this fixed guiding pin was replaced by a drill hole, in which guiding pins of different diameters could be mounted. The counterbore was invented

Counterbores are used, wherever a hole that has already been made has to be countersunk. This countersink has a flat bore bottom and is therefore perfectly suited to take up washers, nuts or screw connections in general. This connection method is very often used in timber construction, e.g. to connect beam constructions with each other. Optical reasons or even statics often specify that these connections should be made invisible, i.e. that the screw heads should be countersunk. Usually these works are made in soft wood. But increasingly often we find optically very beautiful hard woods in timber constructions which make it really difficult for the counterbores as these were usually created exclusively for the use in soft wood. Different with the Bormax® WS prima, long version, which is still known as a counterbore today.

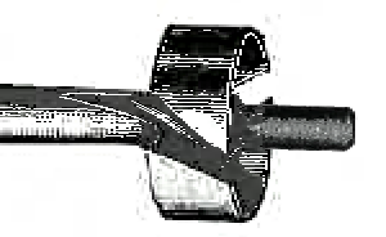

The Bormax® WS prima long version is made of alloyed tool steel. Instead of a fixed centre point it has a drill hole with lateral clamping screw for a pilot drill or a guiding pin.

Included in the delivery scope is a centre drill, which can be mounted perfectly in this drill hole as it has a clamping surface for a safe fixation.

You can replace this centre drill with a guiding pin. Please order that guiding pin separately in the needed diameter.

The drill bits with diameter 20 up to 35 mm have a mounting hole of 8,0 mm for the intake of the pre-drills or guiding pins. All drill bits with larger diameters have a hole of 10,0 mm.

Centre drills and guiding pins are offered with both shank diameters. Please note this when selecting the pins.

Included in the delivery scope is a centre drill, which can be mounted perfectly in this drill hole as it has a clamping surface for a safe fixation.

You can replace this centre drill with a guiding pin. Please order that guiding pin separately in the needed diameter.

The drill bits with diameter 20 up to 35 mm have a mounting hole of 8,0 mm for the intake of the pre-drills or guiding pins. All drill bits with larger diameters have a hole of 10,0 mm.

Centre drills and guiding pins are offered with both shank diameters. Please note this when selecting the pins.

We used to make these counterbores with the classic geometry of a cylinder boring bit.

For quite some time we have transferred the geometry of the Bormax® to these counterbores and therefore call them today: “Bormax® WS prima long version”.

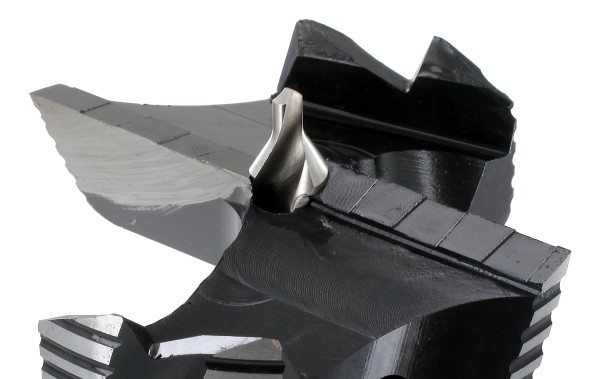

What makes the Bormax® prima so special: Two main cutting edges with a toothing on the top side cut the wood. The teeth are mounted in such a way that they are staggered by the chamfers on the cutting edges.

This toothing also has the effect of chip breakers. But before the main cutting edges can do their job, the taper taps have to make the first cut into the wood.

What makes the Bormax® prima so special: Two main cutting edges with a toothing on the top side cut the wood. The teeth are mounted in such a way that they are staggered by the chamfers on the cutting edges.

This toothing also has the effect of chip breakers. But before the main cutting edges can do their job, the taper taps have to make the first cut into the wood.

The result is a proper surface of the hole frame without any tearings. The traditional Forstner bit has a closed circumferential cutting edge. This causes higher temperatures and friction.

In order to avoid this completely, the Bormax® WS prima long has new circumferential cutters with grooves. These are working like many small taper taps. The head of the Bormax® is fitted with fins,

which have the effect of cooling fins. The result is a maximum reduce of the heat development.

The result is a proper surface of the hole frame without any tearings. The traditional Forstner bit has a closed circumferential cutting edge. This causes higher temperatures and friction.

In order to avoid this completely, the Bormax® WS prima long has new circumferential cutters with grooves. These are working like many small taper taps. The head of the Bormax® is fitted with fins,

which have the effect of cooling fins. The result is a maximum reduce of the heat development.

Before the shank of the tool was cylindrical, now it is manufactured hexagonal. This avoids that the drill bit turns in the drill chuck. It has proved particularly successful with larger diameters. The Bormax® prima long version is available in metrical sizes from Ø 25 mm up to 120 mm and also in different INCH sizes. Further we offer three different sets in wooden cases.

Counterbores were constructed for countersinking only in soft wood. This is different with the Bormax® prima long. With the short centre drill, which is included in the scope of delivery,

you can use the tool like a normal Forstner bit or Bormax®. For drilling wood head pieces, you can mount the tip so, that it protrudes a bit more from the drill head. The Bormax® gets better guided,

which is especially desirable for drilling in wood head. If you want to drill diagonal you should separately order the long HSS pre-drill bit with an effective length of 50 mm.

With the mounted pre-drill you can also spot-drill your wood surfaces in almost all angles, without gliding off. No matter if you are drilling in soft wood or European hard wood.

Thanks to the clever geometry of the Bormax® prima it is perfectly suitable for both applications.

which is especially desirable for drilling in wood head. If you want to drill diagonal you should separately order the long HSS pre-drill bit with an effective length of 50 mm.

With the mounted pre-drill you can also spot-drill your wood surfaces in almost all angles, without gliding off. No matter if you are drilling in soft wood or European hard wood.

Thanks to the clever geometry of the Bormax® prima it is perfectly suitable for both applications.

Here is a little trick in case you want to drill freehand a hole with a specially large diameter: Drill a hole at the desired location with a brad point drill bit of 32 mm.

Please order the guiding pin with diameter 32 mm separately and mount it in your Bormax® prima long. The hole already drilled serves as a guide for the guiding pin now.

By this trick you will be able to drill freehand a hole of 80 mm in soft wood! Correspondingly smaller in hard wood. Nevertheless, you should use a powerful machine for this application that has a separate handle

By this trick you will be able to drill freehand a hole of 80 mm in soft wood! Correspondingly smaller in hard wood. Nevertheless, you should use a powerful machine for this application that has a separate handle

Of course you can also use the Bormax® WS prima classically as a counterbore. For this application you use an auger bit to drill a hole in a wood construction. Mount the separately ordered guiding pin in the same diameter in your Bormax® prima and produce without any effort the sinking in the desired depth, e.g. for your screw connections. By the way: the suitable dimension of the washer/screw is regulated by various DIN standards.

Good for you to know: The FAMAG guiding pins of the product line 1619 are always manufactured 0,5 mm below the nominal dimension. This ensures that there is no friction between the pre-drilling and the guiding pin and no chip can bother.

The Bormax® prima is the only Forstner bit with exchangeable centre drill/guiding pin, toothed main cutting edges and circumferential cutter with longitudinal grooves on the market. No matter whether in the short or long version. The geometry is patent protected. It is manufactured in Germany and therefore a real “Made in Germany” tool. Due to its unique selling points it belongs to the DELTA-F family of FAMAG.

- universally applicable as Bormax® with inserted pre-drill or as counterbore with inserted guiding pin

- precise setting and perfect guiding properties with inserted pre-drill in freehand operation

- nearly no heat generation thanks to the ingenious geometry of the interrupted circumferential cutting edge with cooling effect

- very good chip removal due to the chip breakers on the main cutting edges

- due to its geometry it also drills perfectly in European hard wood

- the hexagonal shank avoids turning in the drill chuck

- still has the unique Bormax® geometry after regrinding

Overview of the most important details:

| Product Line | 1614 | |

|---|---|---|

| OØ | 20 - 35 mm | > 35 mm |

| StemØ | 13 - 20 mm | 20 mm |

| SØ | 13 mm | |

| IØ | 8 mm | 10 mm |

| Overall Length | 140 - 145 mm | 150 - 160 mm |

| Effective Length | 90 - 95 mm | 100 - 110 mm |

| Material | Allloyed Tool Steel | |

| Speed | 1.000 rpm | 500 rpm |

| Packaging | Cardboard Tube | |

| PU | 1 | |

(to the product)

(to the product)

We have more than 30 single sizes from Ø 20 up to 120 mm and three sets in high quality wooden cases available in our product range. Both, the Bormax® and the wooden case as well are “Made in Germany”! We deliver the single tools with mounted, short centre drill and a suitable allen wrench for the lateral clamping screw. You may order as accessory our long HSS pre-drill bits in order to being able to drill diagonal holes with the Bormax® prima. In case you use the Bormax® prima as classical counterbore, we offer different guiding pins: Pins with a shank Ø of 8,0 mm (for Bormax® prima long Ø 20 up to 35 mm) are produced from diameter 8,0 up to 22,0 mm. For Bormax® prima long from a diameter larger than 35 mm, you need guiding pins with a shank diameter of 10,0 mm. We produce those from 10,0 up to 32,0 mm. HSS centre drills are available with diameter 8,0 and 10,0 mm – in short and long version.

(to the product)

If you want to produce sinkings with a defined depth, we offer a rotating depth stop. This depth stop has a central bearing with a hole and can be put on the Bormax® prima long with dimensions 40 up to 90 mm. All Bormax® prima have the same stem diameter. Also included in the scope of delivery is a suitable allen wrench for fixing the depth stop on the stem. These depth stops are covered with a yellow powder coating so that they are insensitive to the environment.

(to the product)

Another possibility to make exact countersinks is the FAMAG depth guide (article No. 1405.210). Put your machine (Euro Ø 43 mm) in the depth guide, adjust the lowering depth with help of the depth stop and go…The maximum drilling depth is 200 mm and the maximum diameter of the Bormax® prima long is 90 mm. This depth guide is constructed very compactly with external dimension of the foot of 150 mm only. Very practical in use is that this device has an additional handle. This allows you to ideally vary the feed without using an additional handle of a machine. Please note, however, that considerable forces can occur, especially with larger diameters. Secure the device and use a powerful machine.

It is always good to have everything you need in one set. We offer three different sets in wooden case:

(to the product)

Art.-No. 1614.509: You find the Bormax® prima long drill bits with diameters 50, 60 and 70 mm in a high quality wooden case (made in Germany). All Bormax® are fitted with a short centre drill. Further you find each one guiding pin in diameters 14, 18 and 22 mm in that set. In order to use the Bormax® prima in a machine with Morse Cone 2 intake, we have added a Morse Cone 2 fix adaptor with interior diameter of 13 mm. It can be perfectly put on the different Bormax® prima and is fixed with two clamping screws. Finally there is a rotating depth stop 1619.100 included in that set.

(to the product)

Art.-No. 1614.510: Also this set is delivered in a high quality case „Made in Germany“, but includes Bormax® prima long with diameters 40, 50 and 60 mm. Further contents: Three guiding pins with diameters 12, 14 and 18 mm as well as appropriate FAMAG auger bits with an overall length of 320 mm – with the same diameters as the guiding pins. The only difference of the third set Art.-No. 1614.511 is the diameter of the largest guiding pin resp. auger bit with 20,0 mm.

(to the product)