The FAMAG tool factory was just nine years old when Benjamin Forstner invented the Forstner drill bit in far America. When exactly his invention reached Europe or rather the “Bergisches Land” is uncertain.

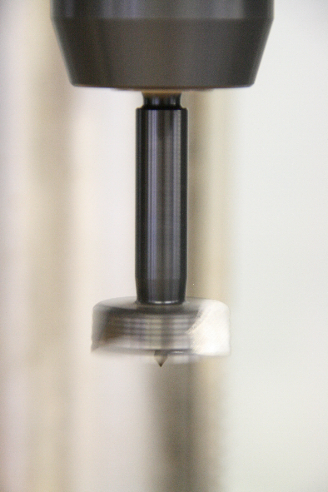

On the other hand it is clear that since this invention users have always tried to drill holes in an exact alignment.

Anyone who has ever tried drilling with a winch and an ancient Forstner drill bit can confirm that this is by no means easy without the necessary practice.

Later in history water-powered wheels and transmission belts were used to drive “drill machines”. The difficult guidance that had been carried out by humans, has been taken over by machines now.

On the other hand it is clear that since this invention users have always tried to drill holes in an exact alignment.

Anyone who has ever tried drilling with a winch and an ancient Forstner drill bit can confirm that this is by no means easy without the necessary practice.

Later in history water-powered wheels and transmission belts were used to drive “drill machines”. The difficult guidance that had been carried out by humans, has been taken over by machines now.

If today highly accurate aligned holes are made, this usually happens in the workshops on stationary tables or box column drills. Line drilling machines are also to be mentioned but increasingly CNC machines are practice nowadays. Spiral drill bits and cylinder head boring bits are likewise used here.

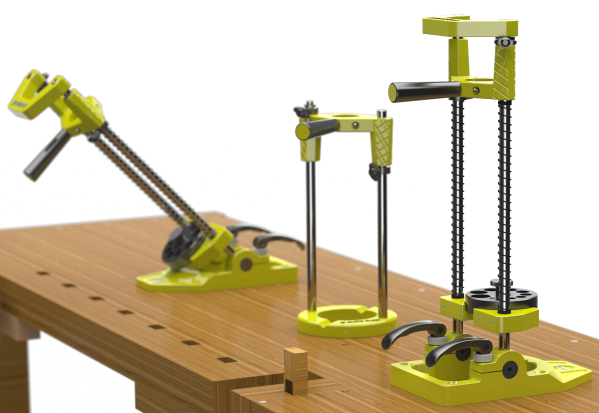

But what to do if such an exact vertical drilling has to be made on a construction site or during assembly? Mobile drill rigs in which a power drill can be fixed are providing essential services here. In fact many users have made bad experiences with the poor quality of cheap drill rigs. If we meet the professionals at the exhibitions, the testing hand movement is always the same: First the upper bridge of the FAMAG depth guide, in which the machine is hold, is tested with a rotary motion for stability. In the following it is tested if the mentioned guide bridge can be moved easily up and down without any play. The facial expression is always the same and confirms that this guide depth will work properly.

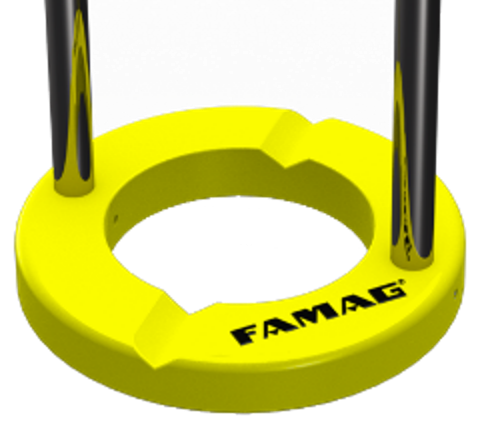

The small version of the FAMAG depth guides consists of a circular foot with an external diameter of 150 mm and an internal diameter of 90 mm.

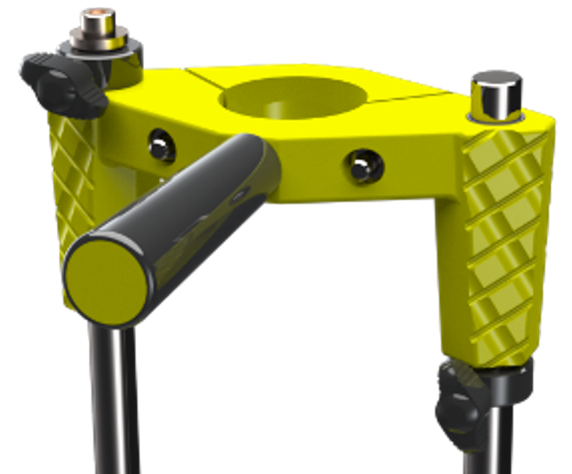

In this base two guide columns made of stainless steel find a stable hold at an exact angle of 90°. At the other end of the columns the guide bridge is mounted for a safe holding of all machines with EURO holder.

By means of two depth adjusters the upper and lower height can be infinitely limited.

In this base two guide columns made of stainless steel find a stable hold at an exact angle of 90°. At the other end of the columns the guide bridge is mounted for a safe holding of all machines with EURO holder.

By means of two depth adjusters the upper and lower height can be infinitely limited.

The components of this device are made of aluminium cast. In order to protect it against corrosion we have powder coated the depth guide – in FAMAG yellow!

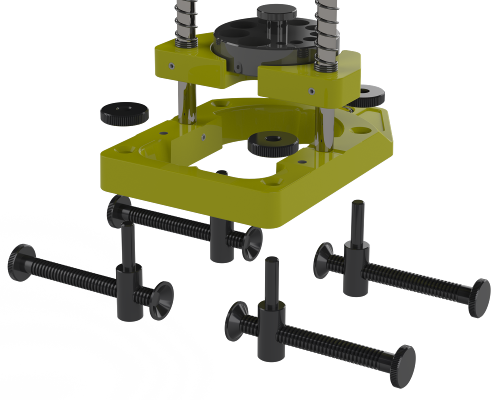

The large FAMAG depth guide is very similar in construction: However, it has a square foot with external dimensions of 250 x 150 mm. In addition four holes are drilled to hold fixtures. Please order these fixtures separately.

Also this depth guide has a maximum internal dimension of 90 mm. The upper end of this guide depth is fitted with a stabilizer. This stabilizer connects the two guiding columns and gives an additional stability during application.

You release the two machine screws of the guide bridge with the attached Allen key and then you mount your machine with EURO hold (Ø 43 mm).

Between the machine chuck and the foot of the device you have sufficient space to fix your drill tools. For cylinder head drills we recommend the Bormax prima product line.

These are available in diameters from 15 up to 120 mm. For coated boards you can choose between the TCT Bormax³ prima, the TCT cylinder boring bit or the TCT Bormax³.

It is to mention that the internal diameter of the foot of the guide depth is 90 mm. Therefore you should use a drill tool with a maximum diameter smaller than 90 mm.

Of course you can also use spiral drill tools in these depth guides. The maximum drilling depth of the small depth guide is 210 mm and that of the large version 320 mm.

It is to mention that the internal diameter of the foot of the guide depth is 90 mm. Therefore you should use a drill tool with a maximum diameter smaller than 90 mm.

Of course you can also use spiral drill tools in these depth guides. The maximum drilling depth of the small depth guide is 210 mm and that of the large version 320 mm.

Since the depth guide is fitted with two depth adjusters you can set the sinking depth as well as the upper limit so that you do not have to pull the machine to the end position every time. This can be very pleasant if you use a drill tool with a small overall length.

We no longer do aluminium casting in Remscheid! The components of this aluminium device are produced for us. Clearly according to our strict factory standard in the well-known FAMAG quality. The processing of the components is done on our CNC machines in our plant, the assembling of the new drill rigs is done in our factory as well. The drill rigs are characterized by their high stability and low weight as they are made of aluminium. The quality of these drill rigs and the price / performance ratio are excellent. Due to this interaction the drill rigs belong to the DELTA-F family of FAMAG.

- compact and robust but lightweight depth guide due to the aluminium material used

- easy movement of the guide bridge thanks to ground guide columns made of stainless steel

- compatible with all electric machines with Euro neck (Ø 43 mm)

- two infinitely variable depth adjusters

- clamping possibility on timber rafters by means of four clamping elements which are available in the accessories of the model with square foot

Overview of the most important details:

| Art.-Serie | 1405.210 | 1405.320 |

|---|---|---|

| Foot outside | 150 mm | 200 x 150 mm |

| Foot inside | 90 mm | 140 x 90 mm |

| Drilling Depth | 210 mm | 320 mm |

| For Drill Length | 240 mm | 350 mm |

| Packaging | Carton | |

| PU | 1 | |

(to the categorie)

In case the drilling depth of 210 mm respectively 320 mm is not sufficient, we recommend the fixed drill rigs of our product line 1403. We offer these for drill lengths of 320/460 and 650 mm. In case you want to drill in a different angle than 90° you should use our pivoting drill rigs of product line 1404. With this alternative item an angle of 45-90° is infinitely adjustable. Also these drill rigs are produced for drills with an overall length of 320/460 and 650 mm.

(to the product)

If you want to drill holes for palings of a staircase, we offer a pivoting drill rig for stair construction, our product line 1406. This is designed for drill tools up to an overall length of 350 mm and is infinitely rotatable from 45-90°.

(to the product)

As accessory we offer individual fastening devices for all drill rigs. These fit universally on all drill rigs and the large guide depth with square foot.

With the universal drill chuck adapter, you can flexibly use a wide variety of machines, regardless of their diameter. The adapter can be easily mounted into the existing machine holder of the drill stand and features a sturdy hexagonal shank that ensures secure clamping of all types of machines.

(to the Product)