More and more wood turners appreciate the “cool head” of Bormax® 2.0. Due to its unique geometry, it is also possible to drill into end grain.

But what makes the Bormax® 2.0 so special?

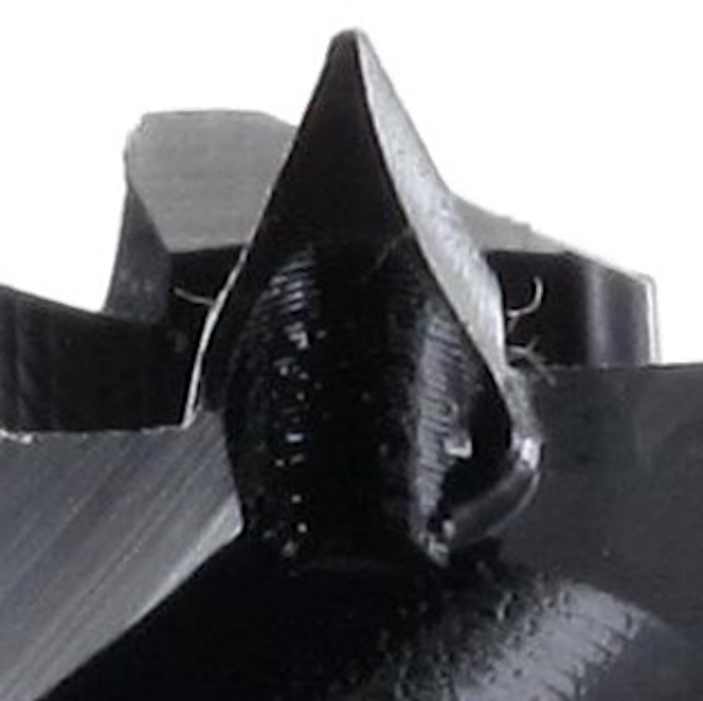

The centre point enables a precise positioning. The tip has a twisted geometry with a cutting effect which makes a clear less feed force necessary.

The centre point enables a precise positioning. The tip has a twisted geometry with a cutting effect which makes a clear less feed force necessary.

The main cutting edges are fitted with grooves that have a chip breaking effect and thus enable a faster drilling with less feed force. No more long chips clogging the hole.

The main cutting edges are fitted with grooves that have a chip breaking effect and thus enable a faster drilling with less feed force. No more long chips clogging the hole.

The greatest weak point with a conventional Forstner bit is the friction and thus the heat that is generated on the closed circumferential cutting edge during drilling. Already with the Bormax® 1.0 it has been possible to reduce this considerably due to the serrated circumferential cutting edge in wave form. With the cooling fins of the Bormax® 2.0 the heat development could be reduced to a minimum.

The greatest weak point with a conventional Forstner bit is the friction and thus the heat that is generated on the closed circumferential cutting edge during drilling. Already with the Bormax® 1.0 it has been possible to reduce this considerably due to the serrated circumferential cutting edge in wave form. With the cooling fins of the Bormax® 2.0 the heat development could be reduced to a minimum.

For all wood turners who work exclusively with hard woods we recommend our Bormax³. This is fitted with a high-quality carbide tipping and therefore has an even longer service life.

For all wood turners who work exclusively with hard woods we recommend our Bormax³. This is fitted with a high-quality carbide tipping and therefore has an even longer service life.