We at FAMAG believe, that in ancient times a clever inventor had the idea of forming a saw in a circular way in order to weld the beginning to the end.

Now all that was missing was a hold for the machine and the hole saw was invented. We here in Remscheid also think that the term of the tool is very appropriate,

because in fact you do not drill but saw in the material. For this reason, we do not say: We drill a hole with a hole saw. We name it: “We saw a hole with a hole saw.“

because in fact you do not drill but saw in the material. For this reason, we do not say: We drill a hole with a hole saw. We name it: “We saw a hole with a hole saw.“

No idea if the hole saw for metalworking or the hole saw for woodworking was invented first. However, saws with soldered-on bi-metal or carbide elements certainly appeared in the market much later. What has never worked, is using a hole saw for metalworking for wood-based materials. By the way, not the other way either.

When we talk to the woodworking professionals about the use of hole saws, we often get a frown, as they have made bad experiences with bi-metal hole saws. Of course,

the bi-metal hole saw is designed for metalworking and does not work really satisfactory in wooden materials, respectively only for 10 seconds. Within this time,

relatively coarse wood chips are produced during the processing of wood, which clog the small teeth of the bi-metal hole saw and cannot be removed. What is happening now?

Nothing – it does not go on a millimetre and if we let the machine continue to rotate, the hole saw starts to give smoke signals!

the bi-metal hole saw is designed for metalworking and does not work really satisfactory in wooden materials, respectively only for 10 seconds. Within this time,

relatively coarse wood chips are produced during the processing of wood, which clog the small teeth of the bi-metal hole saw and cannot be removed. What is happening now?

Nothing – it does not go on a millimetre and if we let the machine continue to rotate, the hole saw starts to give smoke signals!

For some years now, however, there have also been hole saws on the market which are fitted with carbide plates and which have larger chip spaces. With these hole saws it is sometimes quite possible to also process wood materials. Here, too, the spirits soon differ when it comes to universal tools that can be used in soft wood, hard wood, coated boards, plaster board, bricks or other materials.

But one thing is always the same and always makes a bad mood: Once you have done the job and finished sawing the hole, the saw core is stuck inside the hole saw. Some hole saws are fitted with holes or slots on their lid. With a screwdriver you can then try to remove the core from inside.

Different with the hole saw system PAROLI® all-round and the new “PUMPSHANK®“ ejector-shaft!

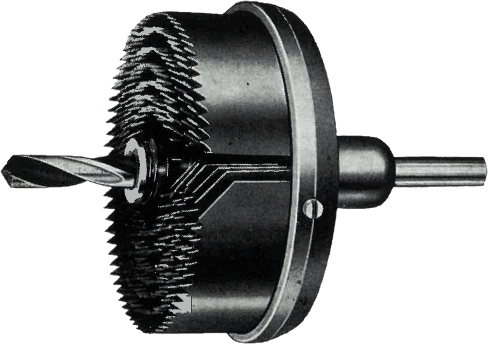

Let us start with the carbide tipped hole saw PAROLI® all-round: There are different possibilities to produce a hole saw. Usually you bend a piece of metal so that it receives a round geometry and weld the beginning to the end. Now a lid with a shank is welded on and the hole saw is finished! The question is, if these hole saws run properly? According to our experience they do not! So we go a completely different way:

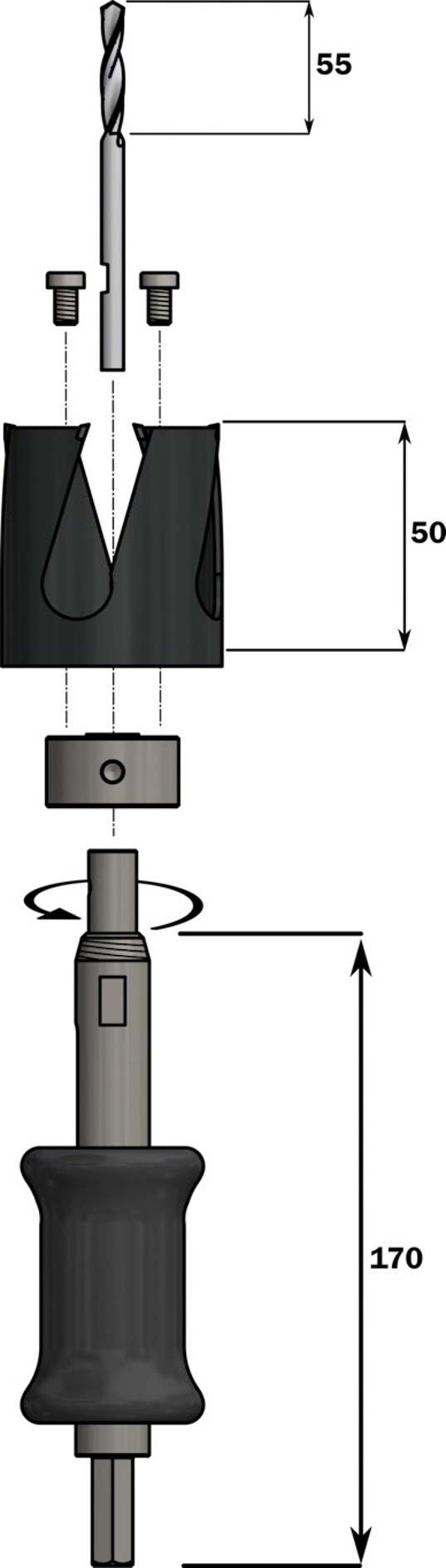

A piece of steel is heated red-hot and forged to a raw body, which already looks almost like a hole saw. These rather rough forgings are turned on a CNC machine. The result is an uninterrupted fibre flow of the base material and perfect concentricity properties! Subsequently, on CNC milling machines the large flutes as well as the insert seats for the carbide teeth are milled. Now an exact processing is requested: Routine hands position the carbide plates, fix them and then solder them to the main body of the hole saw. Once again highest performance is required when the CNC grinding machine grinds the high precision geometry of the teeth. This is the only way to achieve the perfect concentricity of the PAROLI® hole saws and a dimensional stability that you will probably only find at FAMAG!

But with the hole saw alone you will not saw one hole! What is missing now is a spiffy shank.

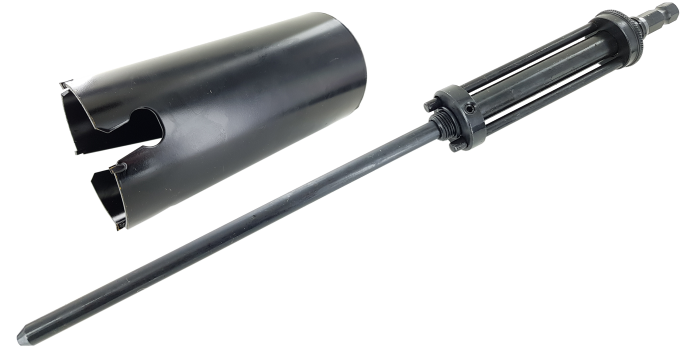

On one side the PAROLI®

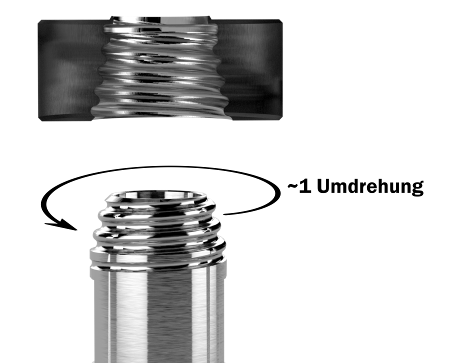

"PUMPSHANK®" ejector-shaft is fitted with a solid hexagonal holder to be held properly in the machine chunk. On the other side we mounted a very special conical exterior thread.

But what for? This precision thread is designed to release an adapter with the same internal thread with less than one turn.

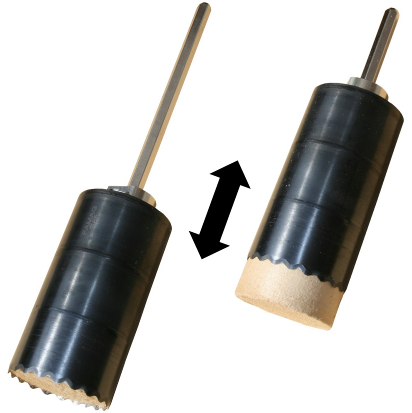

Screw the adapter to a hole saw with help of the enclosed two screws and lock this hole saw with less than one turn on the ejector shank.

You can also call this a quick-action adapter. But that’s not all: The clever finish of the conical thread is designed in a way that a form-fitting connection without any tolerance is created.

This has a maximum positive influence on the concentricity of the hole saws and thus on the dimensional accuracy and the proper surface finish of the hole.

"PUMPSHANK®" ejector-shaft is fitted with a solid hexagonal holder to be held properly in the machine chunk. On the other side we mounted a very special conical exterior thread.

But what for? This precision thread is designed to release an adapter with the same internal thread with less than one turn.

Screw the adapter to a hole saw with help of the enclosed two screws and lock this hole saw with less than one turn on the ejector shank.

You can also call this a quick-action adapter. But that’s not all: The clever finish of the conical thread is designed in a way that a form-fitting connection without any tolerance is created.

This has a maximum positive influence on the concentricity of the hole saws and thus on the dimensional accuracy and the proper surface finish of the hole.

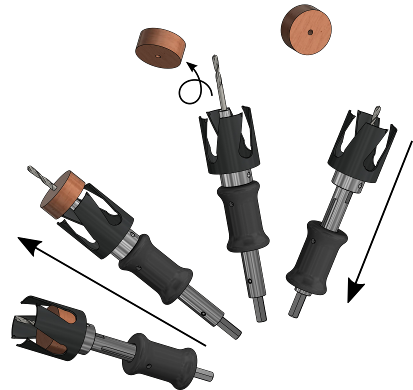

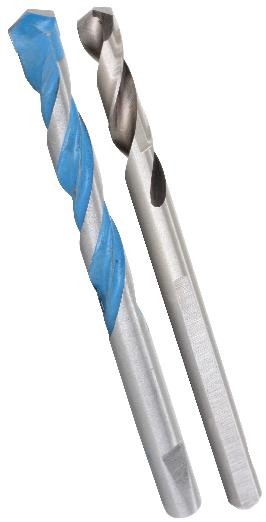

In the front part of the ejector shank you find a 6 mm boring in which a pre-drill finds its perfect fit. But the best is: Inside the shank there is a mechanism. By means of the sliding handle you can push the pilot drill forward for spot-drilling. But it is important as well that that you can use this gliding handle to eject the core after having finished the work.

Connect your PAROLI® 50 all-round hole saw with the enclosed adapter by using the two screws. Now you screw this combination with less than one turn and without any effort onto the PAROLI® PUMPSHANK® ejector-shaft.

Put the hexagon of the PUMPSHANK® in your cordless screwdriver and lock the drill chuck.

Put the hexagon of the PUMPSHANK® in your cordless screwdriver and lock the drill chuck.

Now push the pilot drill forward out of the hole saw by means of the rotatably mounted sliding handle. You are able to precisely spot-drill now. As the sliding handle is mounted rotatably you can hold it during spot-drilling while the machine is running. Beside a perfect guidance you also achieve a safe application for man and machine. After the spot-drilling you retire the sliding grip and you continue sawing with the hole saw. Having finished the complete sawing process you push the gliding handle and the core is ejected easily out of the PAROLI® hole saw!

You will really enjoy working with the PAROLI® all-round hole saws as these are universal hole saws and therefore perfectly suited for the use in many materials such as soft wood, hard wood, board materials like MDF, chip boards - coated or uncoated -, gas concrete as well as gypsum cardboard, plastic materials, sand-lime brick, bricks and tiles of a scratch hardness of 6!

Pay attention to saw in all materials except of stone and tiles with a proper speed.

We offer a fine accessory for countersinking perfectly a cavity wall box: The PAROLI® edge countersink with diameter 68 mm. Just mount this edge countersink between the adapter with the conic interior thread and the PAROLI® hole saw with diameter 68 mm. Now you saw your hole as usual. Subsequently push the hole saw further into the hole so that the carbide teeth of the edge countersink are used. This countersink is designed with an integrated depth stop. This ensures the perfect lowering depth so that the collar of the cavity wall box disappears in the wall. Put the lid on it and you are ready! Also in this combination of tools you can eject the core as usual with the PAROLI® PUMPSHANK® ejector system.

We admit, that it was not very comfortable to work with the predecessor of the PUMPSHANK. The new PAROLI® hole saw system has nothing to do with the old version. The new PUMPSHANK picks up the hole saw without any tolerance, which is reflected in the ideal concentricity of the hole saw immediately. The guidance of the hole saw is perfect. There is much more security in application thanks to the rotatable and movable handle. The dimensional accuracy of the bore hole and the cutting behaviour of the hole saw are really convincing. The core can be ejected very easily! A lot of know how was necessary to develop such a system. The new PUMPSHANK® ejector shaft is manufactured in Remscheid and thus a real "Made in Germany" tool. Due to its unique selling points the new hole saw system PAROLI® belongs to the DELTA-F family of FAMAG

PAROLI® hole saw

- perfect concentricities as these hole saws are forged from one piece of steel

- very dimensionally accurate holes as these hole saws can be mounted on the ejector system PUMPSHANK® without any tolerance

- universally applicable due to the high quality carbide tipping in soft wood, hard wood, coated boards, sheetrock, gas concrete and many others

- very proper drilling pattern thanks to the ingenious polished section of the carbide tipped teeth

PAROLI® PUMPSHANK® ejector system

- compatible with almost all standard hole saws

- precise attachment by safety push handle

- perfect concentricity due to adapter with conical thread

- rapid ejection of the saw core by means of the safety push handle

- the hexagonal shank avoids turning in the drill chuck

Overview of the most important details:

PAROLI® hole saw:

| Product line | 2166 |

|---|---|

| OØ | 40 - 210 mm |

| Effective Length | 50 mm |

| Material | TCT |

| N Wood | 2.500 rpm |

| N Floor Tile | 800 rpm |

| Packaging | Rose-Clip |

| PU | 1 |

PAROLI® PUMPSHANK®: |

|

| Product line | 2166.605 |

| Schaft | hex 13 mm |

| Vorbohrer | 6 mm |

| Adaptor | 1 incl. |

| Packaging | Metal-Box |

| PU | 1 |

(to the Product)

Beside more than 30 single diameters and the edge countersink we offer one set in a solid plastic case. This set of 8pcs consists of the PAROLI® all-round hole saws with Ø 45, 50, 57, 60, 68, 80 mm, one edge countersink cap, six adaptors for the hold of the hole saws, the HSS pilot drill in Ø 6 mm and the PUMPSHANK® ejector shaft. For mounting the adapter on the hole saw we have enclosed the appropriate allen key wrench. You can also perfectly use this key to untighten the adapter from the PUMPSHANK®.

(to the Product)

In case you buy the ejector shaft PUMPSHANK® separately it might be reasonable to have a quantity of adapters. These adapters can be mounted on the different hole saws. So you avoid with each change of the hole saw to change the adapter as well. For this purpose we have a set of 5pcs of adapters incl. the suitable screws. By the way, these adapters can be mounted on all common hole saws from a Ø of 40 mm.

(to the Product)

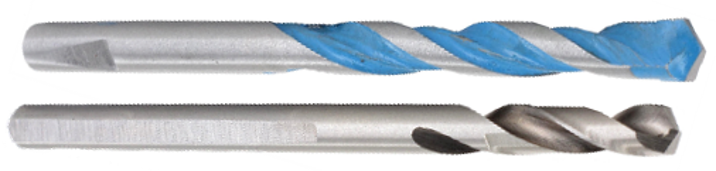

Surely you can also buy separately the pre-drill. No matter if it is made of HSS or carbide tipped for the use in tiles and stone materials.

(to the Product)

If the effective length of 50 mm is not sufficient, we also offer the PAROLI® all-round hole saw with an effective length of 165 mm (product line 2169). Today the PUMPSHANK® ejector shaft cannot be used for this long version PAROLI® 165 hole saw. Please use the old version of our quick ejector shank article No. 2169.310 incl. the enclosed guiding pin. As soon as a PUMPSHANK for these hole saws is available as well, we will inform you through our newsletter.

(to the Product)

In case you want to cut insulation material you will not be very successful with the PAROLI® all-round hole saws. After a few moments the coarse fibres will wrap around the carbide teeth and bring you to despair. For this purpose we offer our PAROLI® 100 insulation hole saw. The geometry of the cutters is similar to a knife for bread and cuts the long fibres of most of the insulating materials in a proper and dimensionally stable way. For more details take a look at the description of product line 2155, which also belongs to the DELTA-F products of FAMAG.

(to the Product)