May be 40.000 years ago the human being invented the drill bit. Over the centuries the drills have been continually improved. One of the really big problems with drilling was to transport the drill material out of the hole. In 1865, at the time of the foundation of FAMAG Werkzeugfabrik, Giovanni Martignoni, a Swiss mechanic, lived in the neighbouring town of Remscheid. He first constructed a drill with twisted grooves after our records. First he filed only one groove into a cylindrical body, later two grooves which were spiral-shaped. From now on the drill material could be transported out of the borehole similar to a screw conveyor. Martignoni’s idea met with great approval and also found the way to America. Already in 1867 American twist drills were presented at the Paris World Exhibition. But actually the invention with this background comes almost from the Bergisches Land; or at least 30 km far away!

In woodworking certainly spiral tools that possessed a polished section of the cone-shaped shell were used first. Twist drills are made of metal, but drills for wood are not made of wood! Much more they differed from the drills for metal by their head geometry. For a better drilling in wood these drill bits were ground with a centre point. In the first FAMAG catalogues there are drills for wood, which even have a kind of taper tap

https://www.ke-next.de/panorama/die-groessten-erfindungen-der-bohrer-103.html

Today drills for wood are used in the industry, the craft, at home and in numerous trades. The field of materials is wider than ever. We have moist soft woods, European hard woods and exotic hard woods from far regions. So far we are talking about processing of solid wood. But today we also find many board materials with completely different compositions. Chipboards and MDF boards are well known. In some cases they have extremely hard coatings that put completely different demands on the drilling tool than the material of the board itself.

Let us take a look at soft wood and the geometry of the drills. During drilling you produce high cube chips. Moist wood or resin increases the problem of removing the large soft wood chips through the spiral out of the boring. Low cost twist drills are mainly produced through “roll rolling”. This means that spirals are rolled into an unhardened blank by using two metal rollers. Too often these tools do have a brittle and rough surface within the spiral which disturbs the transport of the chips. You all know the result: The chips remain hanging in the spiral and block it. The drill is stuffed. For slightly better tools, the spiral is milled into the unhardened blank. In production, time is money and so the used feeds do also produce rough surfaces in the spirals. The result is similar bad, also these tools stuff. Furthermore, in both manufacturing processes the spirals are only hardened after they were finished. This can lead to a hardness distortion, which can often not be completely eliminated even by a subsequent grinding of the outer geometry. The result are twist drills that do not run smoothly.

Let us take a look at the head geometries of the twist drills. At first a centre point is needed. Normally all drills for wood are fitted similarly with such a centre point. In order to receive a hole with perfect edges, especially when you are drilling in soft wood, one or two fine taper taps are needed. For that several working steps are necessary and this has effect on the price. At best you find tools with protruding cutting edges on the outside of the main cutting edges. A real good approach but far from perfect!

In case you want to have low-cost drills for drilling in soft wood only, cost-efficient steel grade may definitely be sufficient. For drilling in hard wood or rigid coatings these steel qualities are not at all convenient.

With all these experiences we decided to produce the perfect brad point drill bit for all hard woods and board materials – with an impressive result.

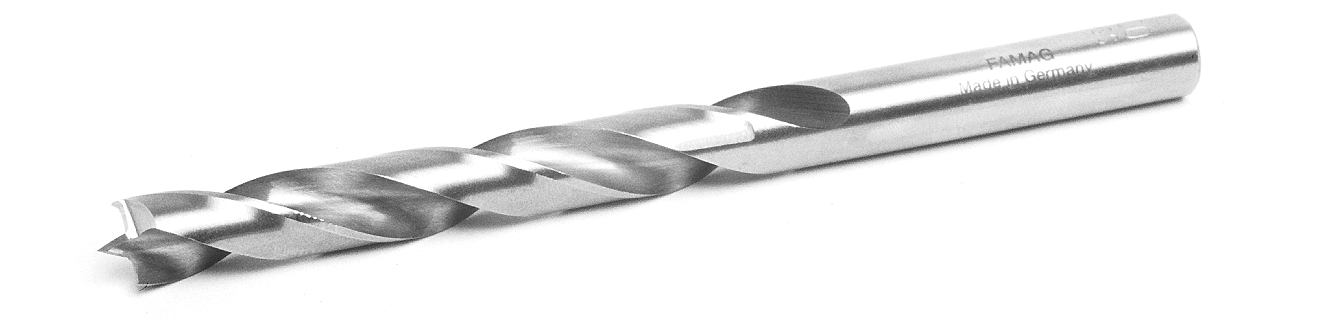

If you want to drill in solid woods or coated boards, you reach good results with drilling tools made of high quality material. In our opinion the most suitable material for wood working is high-speed steel (HSS). Therefore the premium brad point drill bits of our product line 1594 are made of HSS. We use a cylindrical HSS blank. After cutting into lengths, the blank is hardened. We grind two spirals into this now hardened piece by means of two grinding wheels. The result of this first manufacturing step is a spiral blank with perfect concentricity.

Selecting the spiral geometry creates another special feature: Usual spirals have the geometry of a semicircle. On the flanks of these semicircle geometry, however, they can later retain well the chips when working with hard wood. We might get chip jam. Thus, our spiral has a geometry similar to a screw conveyor, with the effect that the chips slide through the spiral during drilling without jamming there. This effect is further enhanced by the extremely smooth spiral surface, achieved during grinding. We call this production method “fully ground”.

But also the head geometry of these tools is fully ground! Our CNC machines follow a tricky program, which allows to create the brad point, two main cutting edges and two taper taps. In the following we relief-grind the main cutting edges to reduce friction forces during application. Traditionally, the smallest diameters of brad point drill bits are 3,0 mm. Different with FAMAG. We are able to manufacture drills of 2,0 mm thanks to this production method. The largest diameter our grinding machine for deep holes can produce is 20,0 mm. But we are also able to manufacture half measures, such as 2,5/3,5/4,5 mm.

The result of this production method is a brad point drill bit of the quality class “Excellent”! A tool made of the best of all HSS materials, with a perfect concentricity and a spiral type, which guarantees an excellent transport of the chips. The two taper taps create a perfect drilling hole circle. The two main cutting edges produce a rapid feed, which is favoured by the ideally designed and particularly smooth spiral.

You can drill without any efforts in all hard woods - and even in rock-hard woods - by using these HSS-G brad point drill bits of excellent class quality. Best results will be achieved in stationary use. These drills do well with high speed. For example, we recommend running the Ø 4 mm at 5.000 rpm. You reach rapid feed rates with these high speeds with best chip removal. The tools are also suitable for freehand use. But you have to use a powerful cordless screwdriver or power drill. Do not try to drill freehand with 1.000 rpm in soft wood. We recommend different tools for this application. To this take a look at the last point.

These drills are perfect suitable for dowel drilling due to their characteristics. The dowel has a perfect fit in the hole due to their dimensional accuracy. No matter if you want to drill only a few holes or if you want to use the drill bit in a CNC machine for serial production. Service life is excellent as we only use high quality HSS material. Beside solid wood you can perfectly use this drill bit for nearly each kind of board material. No matter, if the boards are coated or uncoated. The tricky head geometry is not afraid of even hardest coatings: At first the two taper taps cut razorlike the hole circle of the boring. After that the two main cutting edges lift off the coating without any effort. Summarizing, we would like to recommend these brad point drill bits of the class “Excellent” for all wood materials, hard wood, coated and uncoated board materials.

The brad point drill bits made of HSS-G of that product line have several unique selling points. Some user told us, that after the first use of these tools they will never change to another drill bit any more. There are voices claiming, that these are the best twist drills ever. But please make your personal decision for yourself. The volume development of these tools and the positive experience of their users clearly makes it to a member of the DELTA-F family of FAMAG.

- high-precision drillings thanks to the fully ground finish

- perfectly suitable for all hard woods due to the use of high quality HSS steel

- especially proper drilling pattern due to two grinded taper taps

- perfect chip removal due to the fully ground deep hole spiral

- very fast drilling as these twist drills require high speeds and feeds

Overview of the most important details:

| Product Line | 1594 |

|---|---|

| OØ | 2,0 - 20,0 mm |

| Grading | 0,5 mm ascending |

| SØ | cylindrical |

| Overall Length | DIN 338 |

| Drill Head | with two taper taps |

| Spiral | Deep hole spiral |

| Material | HSS |

| Production Type | fully ground |

| Speed Ø 4 mm | 5.000 rpm |

| Packaging | Rose PVC tube |

| PU | 1 |

Beside the individual diameters from 2,0 up to 20,0 mm we also produce almost all 0,5 mm intermediate size (e.g. 3,5/4,5/5,5 mm etc.). Many interesting sets are available as well. Small boxes with the most common diameters or other sets in wooden boxes, e.g. with countersink. To mention also the sets of 19 or 25pcs in the high quality Rose box. Here you find the diameters from 1,0 up to 10,0 mm in ascending gradings of 0,5 mm. Further included in set of 25pcs you find diam. 10,5 up to 13,0 mm.

If you want to combine a perfect drill and a countersinking with an angle of 90° in one operation step, we recommend our VARIO countersink. It is fitted with a high quality carbide tipping and can be put on all diameters from 3,0 up to 8,0 mm. Important to mention that this countersink is a two-piece tool, pushing on the drill bit from two sides. As a result, the perfect concentricities of these brad point drill bits are not affected. This is particularly important for the smaller diameters like 3/4 and 5 mm. This countersink also fits for all drill bit diameters in intermediate sizes as 3,5 or 4,5 mm. With the high quality tipping it is ideal for use in combination with the HSS-G brad point drill bits of the product line 1594. You will enjoy the high service life.

In case you need larger diameters than 20,0 mm, we recommend product line 1599.2. These are exactly the same tools, but with an overall length of 250 mm. We produce these tools up to a diameter of 25,0 mm. In general this product line is produced with overall lengths of 250, 315 and 460 mm. The smallest diameter always is 3,0 mm and the biggest diameter is 16 mm. Exception is line 1599.2 with up to Ø 25 mm, as mentioned before.

If you want to work soft wood and you are using a cordless screwdriver, which does not reach the necessary speed for this, we recommend the brad point drill bits made of HSS of the product line 1591. These drills are fitted with two protruding cutting edges and a spiral typ N. This will give you good results even at lower speeds.

If you only want to drill in coated chipboards, we recommend product line 1593. This is a carbide tipped version of brad point drill bit. The head is ground in the same way, but the tool has a spiral of type N, as in the removal of chips from chipboard different properties are required.

(to the Product)