In more than 150 years we have gained a lot of experience with regard to the interaction of chip space, depth of chip flute and the stability of an auger bit. Here a few millimeters often decide on the success or failure of a deep hole drilling. There are clear differences in processing soft wood or an exotic hard wood. But no matter what kind of wood you work with, a clean chip transport is extremely important.

In more than 150 years we have gained a lot of experience with regard to the interaction of chip space, depth of chip flute and the stability of an auger bit. Here a few millimeters often decide on the success or failure of a deep hole drilling. There are clear differences in processing soft wood or an exotic hard wood. But no matter what kind of wood you work with, a clean chip transport is extremely important.

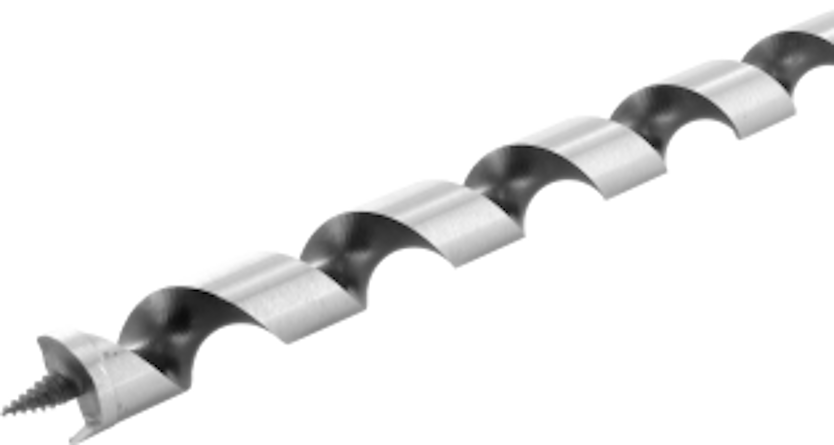

Due to the single cutting edge spiral geometry and the round spiral groove of the FAMAG Lewis auger bit, a perfect chip transport and the necessary directional stability during deep hole drilling are achieved.

Due to the single cutting edge spiral geometry and the round spiral groove of the FAMAG Lewis auger bit, a perfect chip transport and the necessary directional stability during deep hole drilling are achieved.

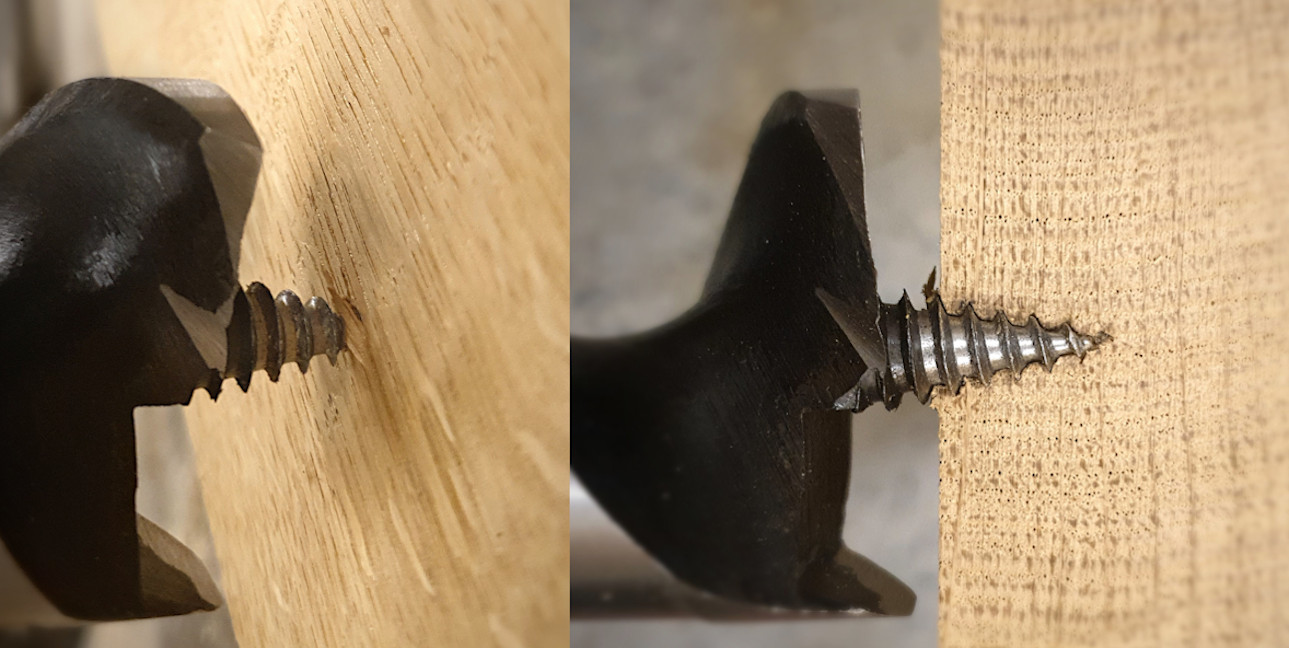

The auger bit pulls itself into the wood with its crest of thread, while the separate taper tap pre-cuts the wood fibres of the outer ring of the boring for a clean hole entry.

Due to the cross-sectional reduced tool head of the FAMAG Lewis auger bit we have less friction and heat development during the processing.

Due to the cross-sectional reduced tool head of the FAMAG Lewis auger bit we have less friction and heat development during the processing.

A long service life is guaranteed as the auger bits are very easily to regrind.

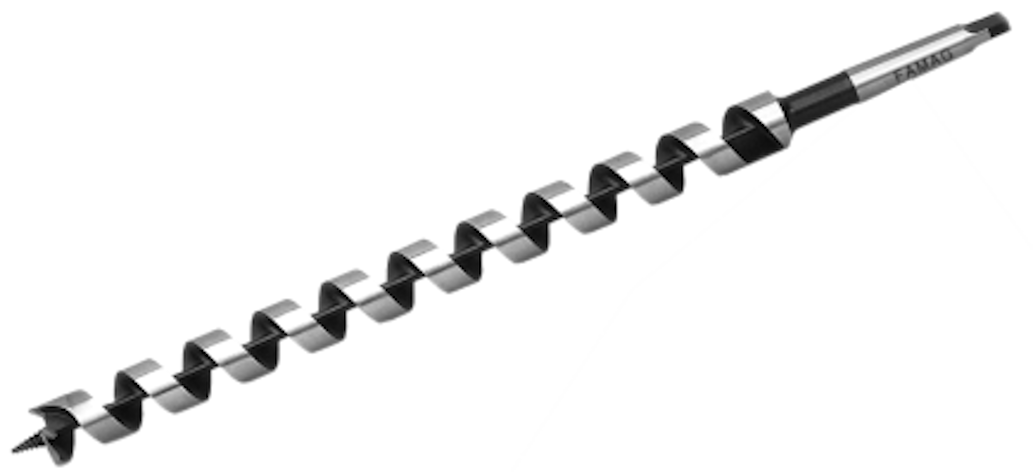

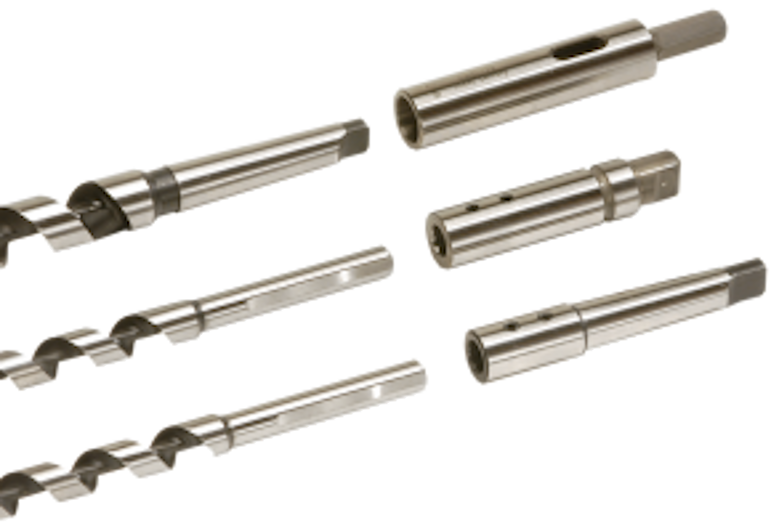

To protect the shanks from twisting in the drill chuck, they are manufactured hexagonal. With a length of 60 mm it is also well suited for joinery systems.

To protect the shanks from twisting in the drill chuck, they are manufactured hexagonal. With a length of 60 mm it is also well suited for joinery systems.

For the different scopes of application with their diverse requirements FAMAG offers a wide range of matching drill bits and accessories.

|

1410 Auger Bit, Lewis Pattern

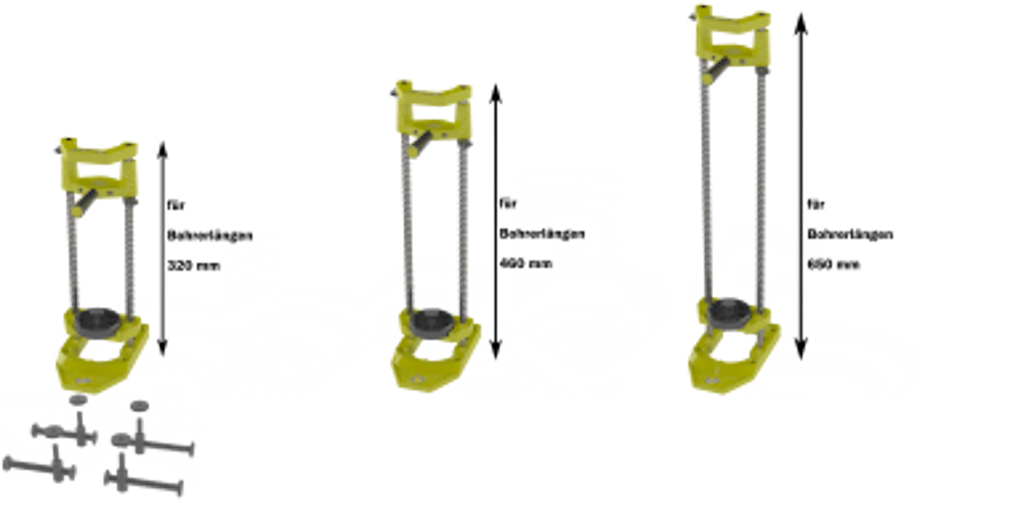

- Length: 235 – 320 mm

- Length: 460 – 650 mm

- Length: 1000 mm

|

1411 Countersink Bormax® 2.0 for Auger Bits 180° |

1492 Auger Bit with Morse Cone Shank No. 2 |

1420 Special Auger Bit for Joinery Machines |

1493 Auger Bit for Hard Wood |

1494 TCT-Auger Bit |

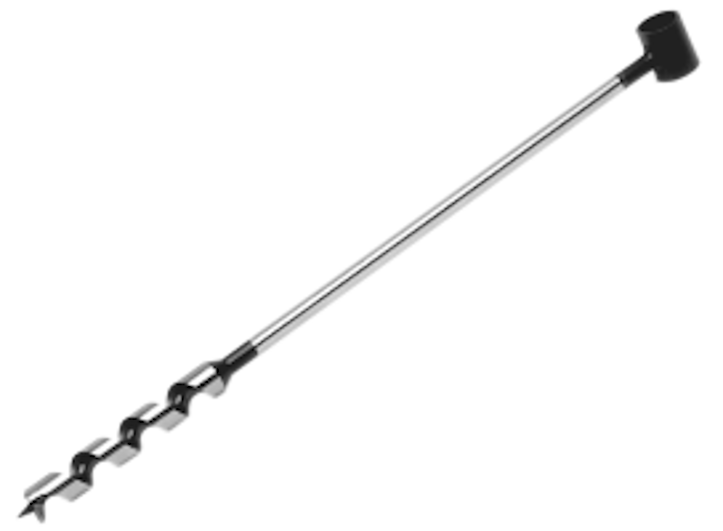

1014 Screw Auger, Lewis Pattern |

1488/89 Special Adapter |

1403 Drill Rig, Fixed Version |

1404 Drill Rig, Pivoting Version |